SERICA 1870

Production

SERICA 1870

The most advanced technology at the service of a constantly controlled production cycle

Lean Production

We invest continually in advanced technologies and directly control the entire production process. To reduce the time of delivery, we have developed a statistical forecast calculation system that manages inventory and organises the production-supply cycle

Latest generation equipment

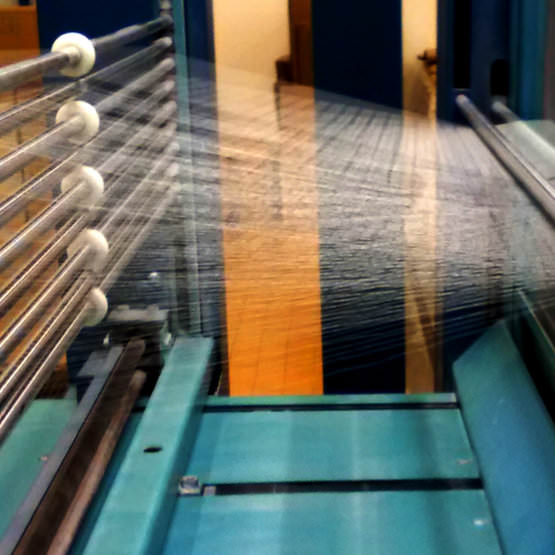

The Warping Department, equipped with two Benninger machines and a Karl Mayer 128 machine for samples, is able to perform any work, also on behalf of third parties

Complete cycle technology

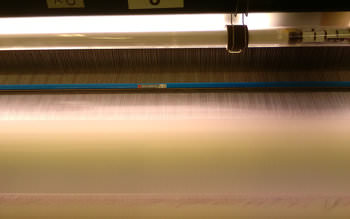

From raw cloth to finished fabric, the in-house control centre backed up by laboratory testing is able to map any defects

SERICA 1870

We are not only excellent weavers. We are the point of reference for fine silk and capable of solving any problem in this area

Our plants and facilities are continually renewed as we control the entire production process ourselves.

The result is that our fabric is the perfect visiting card

SERICA 1870

Departments

The Warping Department, equipped with one Benninger machines and two Karl Mayer 128 machine for samples, is able to perform any work, also on behalf of third parties. We offer the best products and cutting edge technical services.

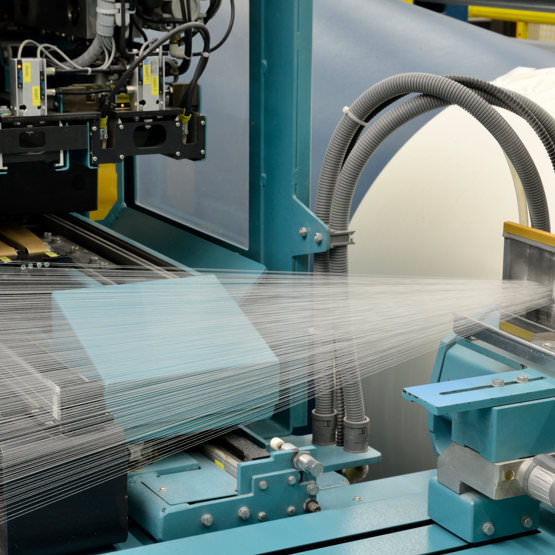

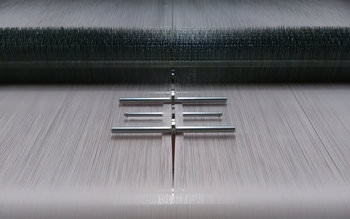

The Weaving Department has 55 latest generation Picanol looms.

The Dyeing, Printing and Finishing department offers a full cycle of:

- star frame scouring

- dyeing (star, torpedo, jigger, boat, flow)

- structured finishing

- full ink jet print cycle (preparation, printing, steaming, rope and continual washing)

SERICA 1870

Chemical managers

The chemical managers stationed at the Follina and Como plants ensure implementation of management systems for any chemical substances used in production. They are continually updated on the latest process methodologies and work systematically to mitigate environmental impacts.